全部分类

水平中开双蜗壳式离心泵Level in the double volute centrifugal pump

|

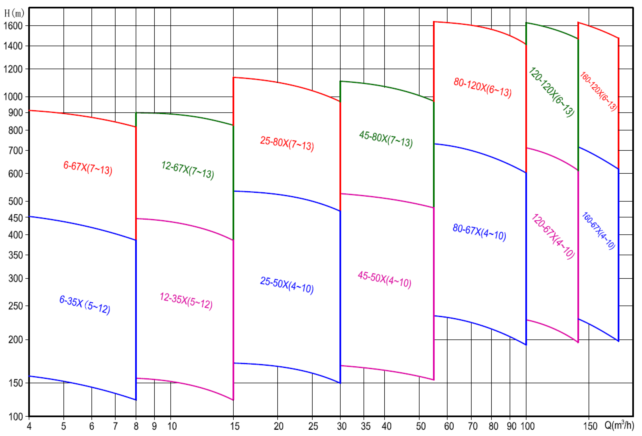

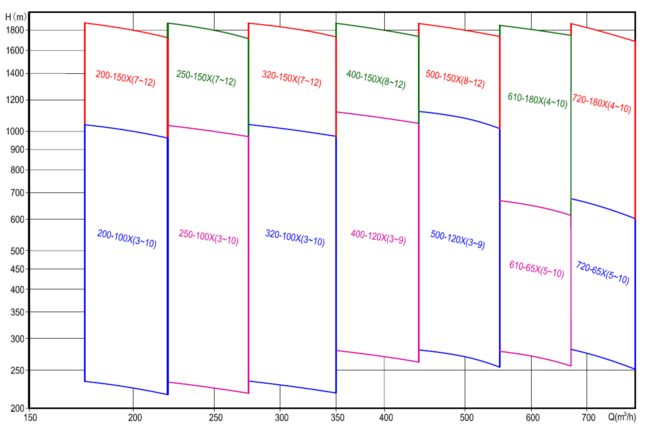

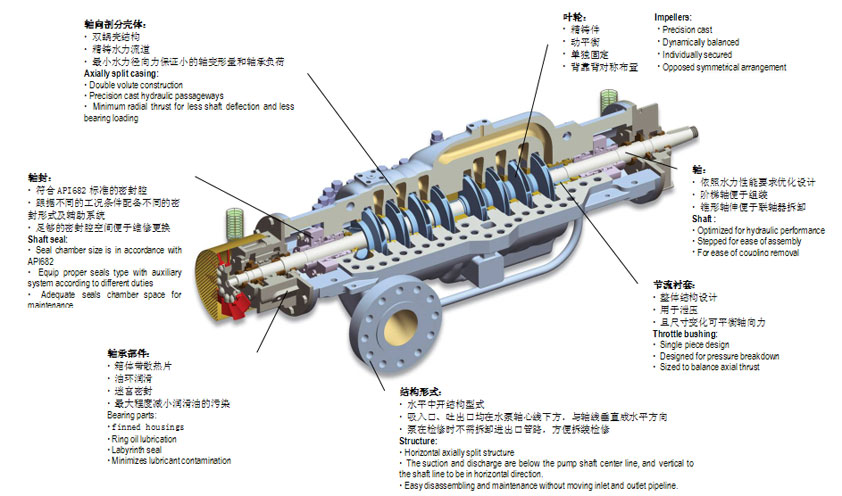

应用范围: AMP型泵为水平中开双蜗壳式离心泵。广泛用于石油化工、石油管线输送、炼油厂、煤化工、电厂、海水淡化等行业。典型工况有电厂锅炉给水,油田注水,煤化工的灰水泵、贫甲醇输送泵等高压工况。 性能范围: 流量:6~1600 m3/h 扬程:~1800 m 压力:10~35 Mpa 温度:-30~200 ℃ 型号说明: AMP 160-120×8 AMP — 水平中开双蜗壳式离心泵 160 — 泵设计点流量(m3/h) 120 — 泵单级扬程(m) 8 — 泵级数 结构特点: 1、AMP泵为水平中开结构型式,吸入口、吐出口均在水泵轴心线下方,与轴线垂直成水平方向,这种结构型式泵在检修时不需拆卸进出口管路,方便拆装检修。 2、叶轮为单吸闭式结构,采用背靠背对称布置,保证转子部件轴向力小,轴承负荷小。首级叶轮也可选用双吸叶轮满足大流量、低气蚀余量工况的要求。 3、泵壳体为轴向剖分双蜗壳结构,精铸水力流道,过流面积大,径向力自动平衡,大大降低轴变形量和轴承负荷。 4、壳体口环为可更换的标准整体口环,舌型固定方式,轴向剖分线位置设置防转销。 5、密封腔体尺寸符合API682标准,可以配置不同结构的密封及冲洗方案。足够大的腔体空间便于密封维护或更换。 |

Application Range: AMP series of pumps are horizontal axially split with double volute casing centrifugal pumps. The pumps are widely applied in fields of petrochemicals, petroleum pipeline transportation, oil refinery, coal chemical industry, power plant, sea water desalination etc. Typical duties are power plant boiler feeding, oil fields water injection, ash water pump for coal chemicals, lean methanol transportation and other high pressure duties. Performance range: Capacity Q:6~1600 m3/h Head H: ~1800 m Pressure p: 10~35MPa(5MPa) Temperature t: -30~200℃ Description of pump type: AMP 160-120×8 AMP — Horizontal axially split double casing centrifugal pump 160 — Pump design point flow (m3/h) 120 — Single stage head (m) 8 — Pump stages Structure Features: 1. Series AMP of pumps have horizontal axially split structure, with suction and discharge below the pump shaft center line, and vertical to the shaft line to be in horizontal direction. It facilitates easy disassembling and maintenance without moving inlet and outlet pipeline. 2. The impellor is single suction close type, with symmetrical back-to-back structure so that ensured small axial force for rotor parts, and small load to bearings. The first impellor can also be double suction to meet duty requirements of big flow and low NPSH. 3. The axially split double volute casing is with hydraulic liquid way fine casted, so that the hydraulic area is bigger, and radial force automatically balanced, which greatly reduced bearing loading and shaft distortion. 4. The casing wearing is exchangeable standard integral wearing, with tongue-type fixed. Stop pin is used on the axially split position. 5. The seal chamber size is according to API682, applicable for different structure of seal and flushing plan. Adequate chamber size is convenient for seals maintenance or exchanging. |

|

6、轴依照水力性能要求优化设计,阶梯轴便于组装,锥形轴伸便于联轴器拆卸。大轴径设计,转子整体刚性好,挠度小,保证了密封环间隙,运行安全、可靠。 7、整体节流衬套,用于泄压,降低密封腔压力,且尺寸变化可平衡轴向力 8、整体平衡管路保证两侧密封腔工作压力相同,不需要用户提供辅助连接。 9、轴承体带散热片冷却,也可选择风扇冷却,满足高温工况要求。安全可靠的迷宫密封环,有效的防止润滑油泄漏和阻止灰尘等杂质进入轴承体内。 10、轴承有两种选配,其一,径向轴承采用滑动轴承,平衡残余轴向力的轴承采用角接触球轴承,最大程度满足转子部件强度的要求;其二,轴的径向轴承和推力轴承均采用滚动轴承结构,径向力由圆柱滚子轴承承受,轴向力由一对预紧的角接触球轴承吸收,径向力与轴向力由不同的轴承承受可大大延长轴承的使用寿命。 泵的转向: 从驱动端看,泵顺时针方向旋转。如用户特殊要求,也可逆时针方向旋转。 |

6. The shaft is optimized designing to meet hydraulic performance requirement. The multidiameter shaft is easy for assembling, and tapered shaft extent is easy for couplingdisassembling. The big shaft diameter design ensured rotor with good stiffness, small deflection, seals ring clearance, and reliableoperation. 7. The whole throttle bushing is used for pressure releasing to reduce the pressure in seal chamber. And the varying of the bushing size can also balance the axial force. 8. In a whole to balance the piping to ensure same working pressure in the seal chamber on both sides. So auxiliary connection is no necessary. 9. The bearings cooling with fan or air are both available to meet high temperature duties. The reliable Labyrinth seals ring can effectively avoid lubricant leaking and ash in bearing house. 10.There are two ways of bearings fitting. One is radial bearings of sliding bearings. The angular contact ball bearings balance theresidual axial force, so as to keep the rotor parts strength to a maximum extent. The other is rolling bearings for shaft radial and thrust bearing. The radial force is born through cylindrical rolling bearing while the axial force is absorbed by a pair of preloaded angular contact ball bearings. So the bearings working life can be greatly prolonged if radial and axial forces are born by different bearings. Rotation direction of pump: The pumps are clockwise rotating viewed from driving end. Counter clockwise is also available if required by users. |